With over 300 years of engineering experience, Savery designs and manufactures high-quality hydraulic systems tailored to your needs. If you're interested in this product, fill in our contact form, and our team will be in touch.

Contact usHydraforce / Oil Control

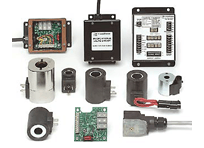

Savery offers one of the most comprehensive lines of hydraulic valves, solenoids and coils and is the UK distributor for the Hydraforce range of products for the mobile and industrial equipment markets, including high performance valves for flow rates of 0.4 to 530lpm and pressure up to 420 bar.

Hydraforce products meet global quality standards including ISO 9001, QS 9000 and CE. Every Hydraforce valve, coil, solenoid, manifold and electro-hydraulic control goes through rigorous testing and inspection to perform beyond industry standards.